COST REDUCTION – FOOD, AGRIBUSINESS & MANUFACTURING

Strategic Cost Reduction

Food, Agribusiness & Manufacturing

CONTEXT

Our client, a leading Australian FMCG manufacturer and packaged fruit processor, was faced with a large legacy manufacturing cost base, which was impacting competitiveness in the face of falling volumes in its core products. Specifically, the client was keen to understand the opportunities to reduce the cost impact of seasonality on its business, whilst also reducing manufacturing costs in general.

CACE Partners was engaged to work with management to develop a strategy to de-seasonalise operations and to identify opportunities reduce manufacturing costs.

INSIGHTS / APPROACH

A highly collaborative approach was taken to leverage management and SME expertise:

- End to end manufacturing strategy developed to significantly reduce the cost impact of seasonality on the business

- 10 workstream established across operations and supply chain

- Collaborative idea generation workshops held in each stream

- 200+ saving hypotheses identified for assessment

- Collaborative approach included risk assessment of each initiative, with a management owner appointed for each hypothesis taken through to exco for approval

- 50+ hypotheses taken through to exco approval and included in the capital masterplan

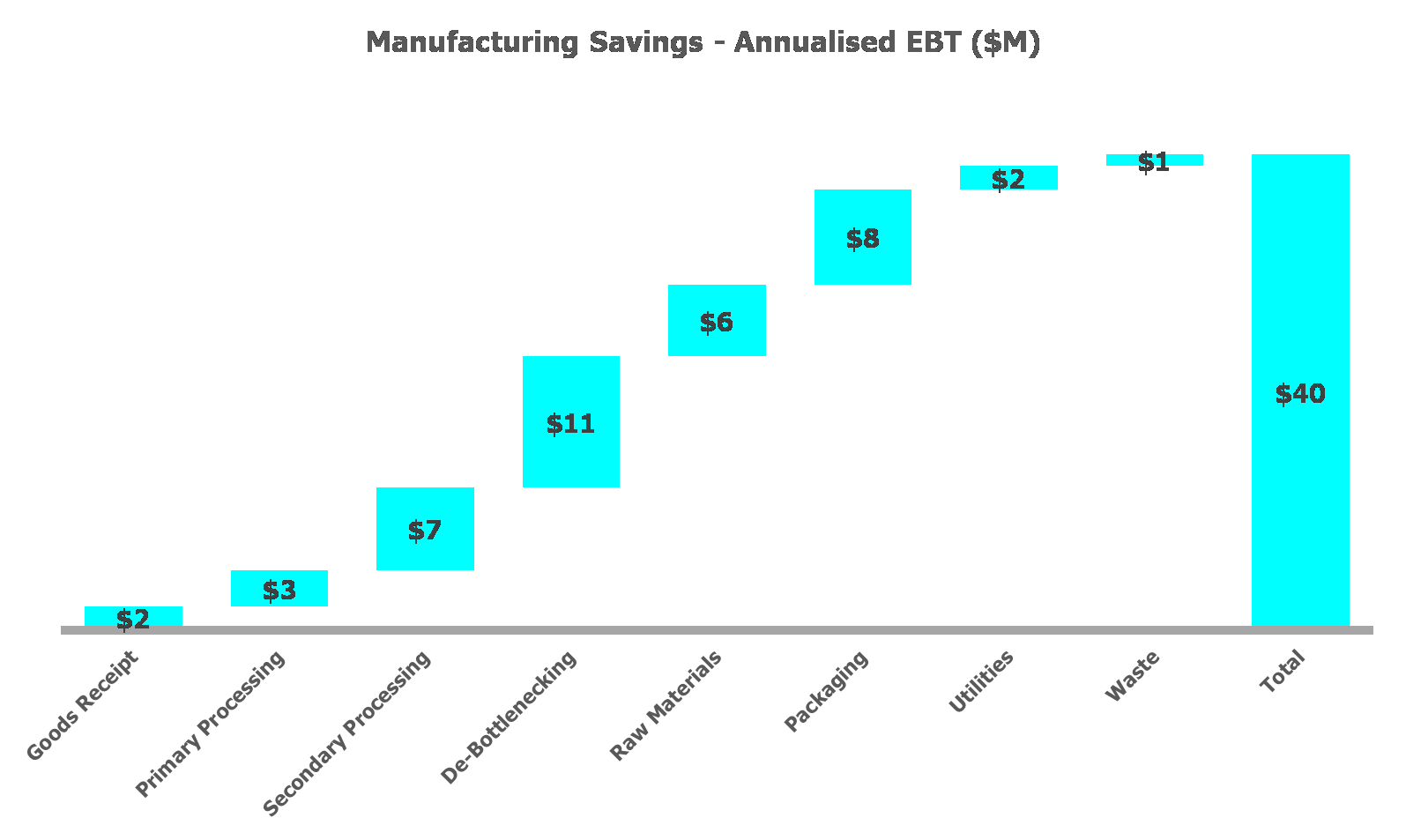

- $35M+ in annualised operational savings (~15% of operational cost base)

RESULTS